Two Successful Cold Flows!

Although we had some trouble predicting our burn times, we've had two successful system cold flows now, both in range for a successful flight (750 lbs of thrust for 5-10 seconds). Even without combustion, the pressure relief was enough to shake our vertical test rig.

With these cold flows out of the way, we are cleared for our lunch date on May 21. We couldn't be more excited. Other areas of the rocket are progressing as well, including refinements to the electronics, boattail, plumbing and pneumatics, and aesthetics.

The Main Launch Valve, Galahad, nestled in the newly machined struts

Nikolai Dorbritz, Kevin Hoo, and Zoe Warp work on the integration between the fins, boattail, and engine thrust struts.

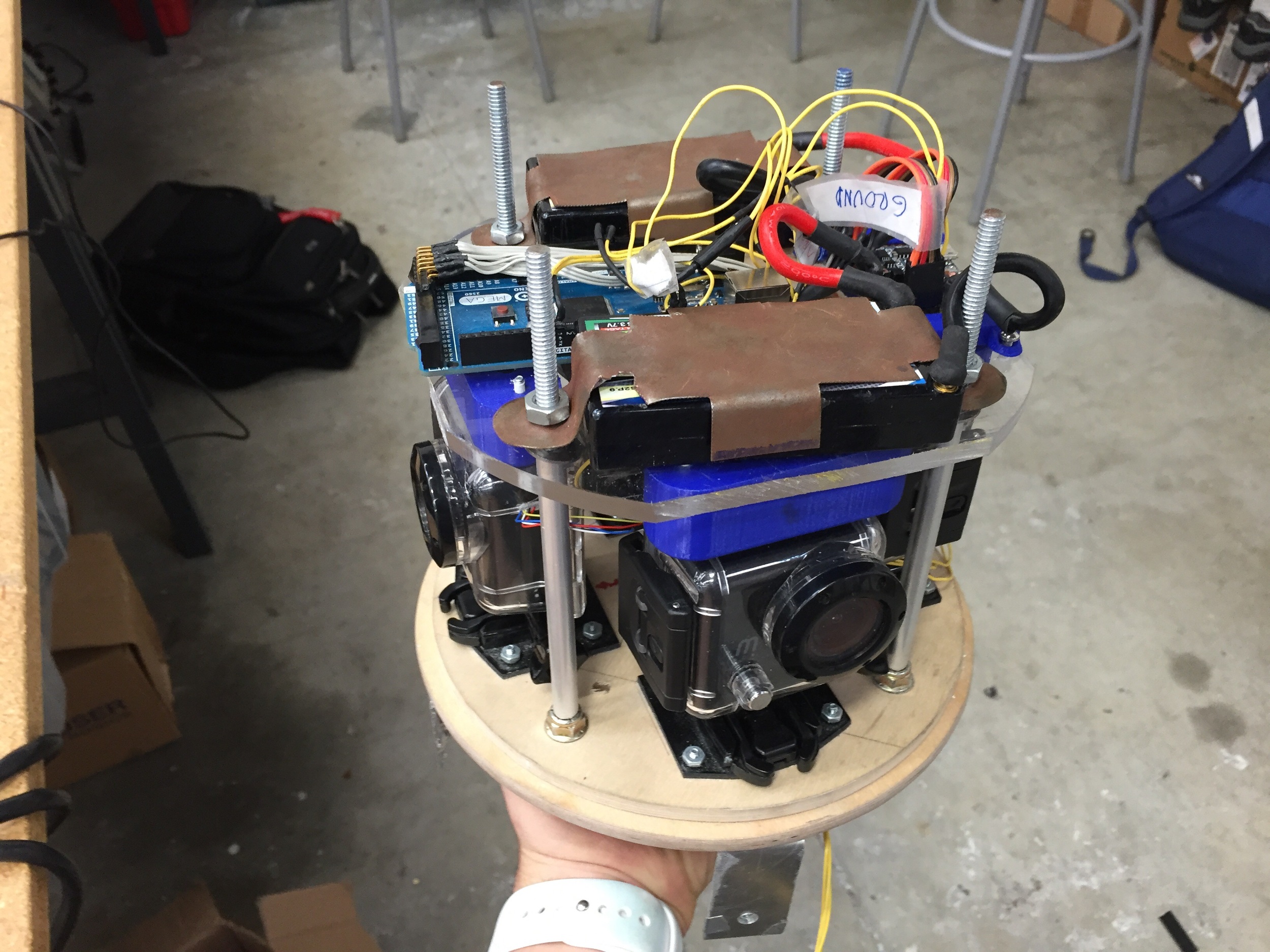

The completed 360 degree camera bay has been the work of half a dozen student engineers in SEDS. It will fly onboard the rocket.

An ABS 3D printed launch lug I've been designing will guide the rocket along a 1.5" rail during its initial flight.